HOW DOES A

WATERJET MACHINE

WORK?

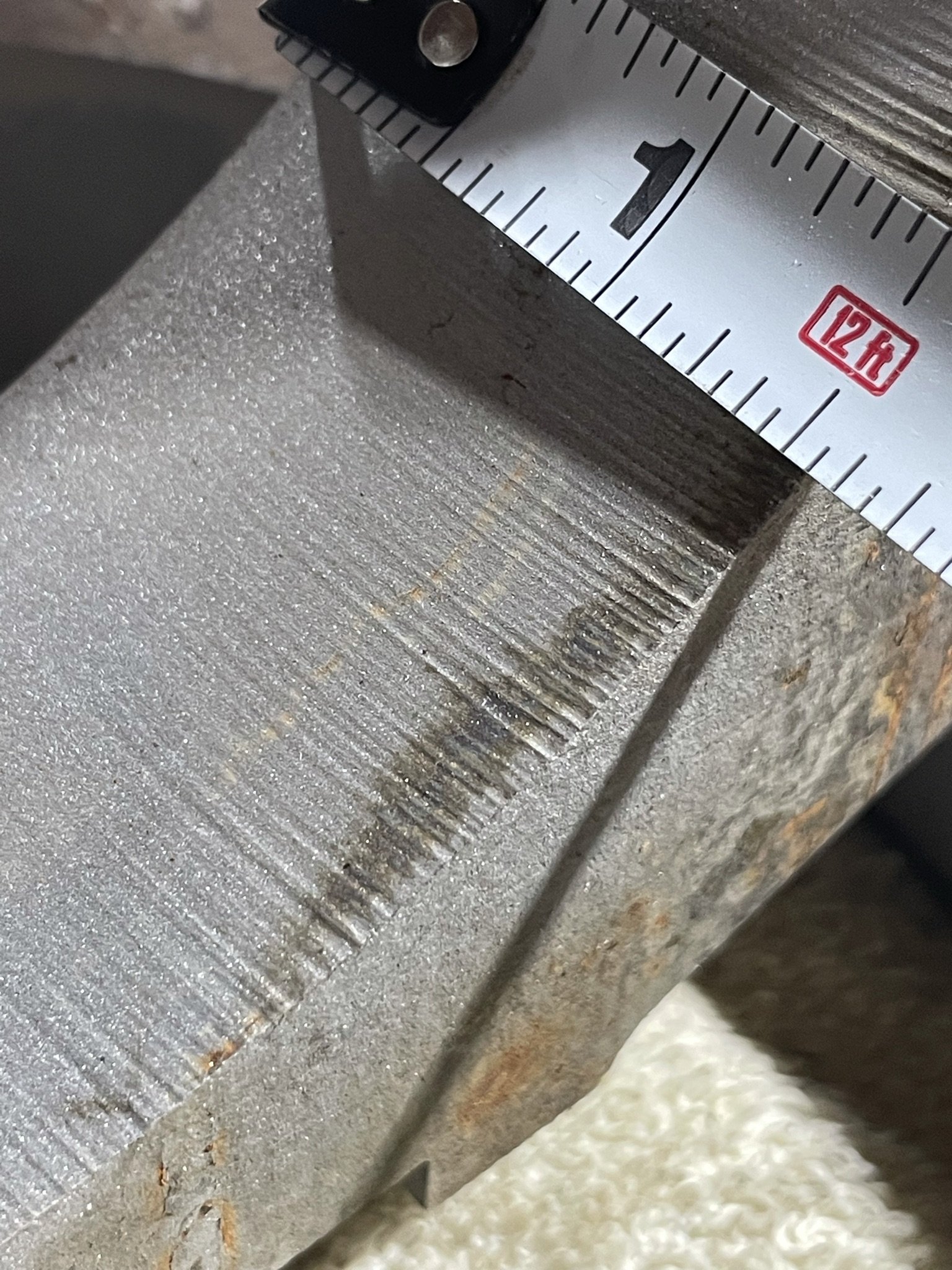

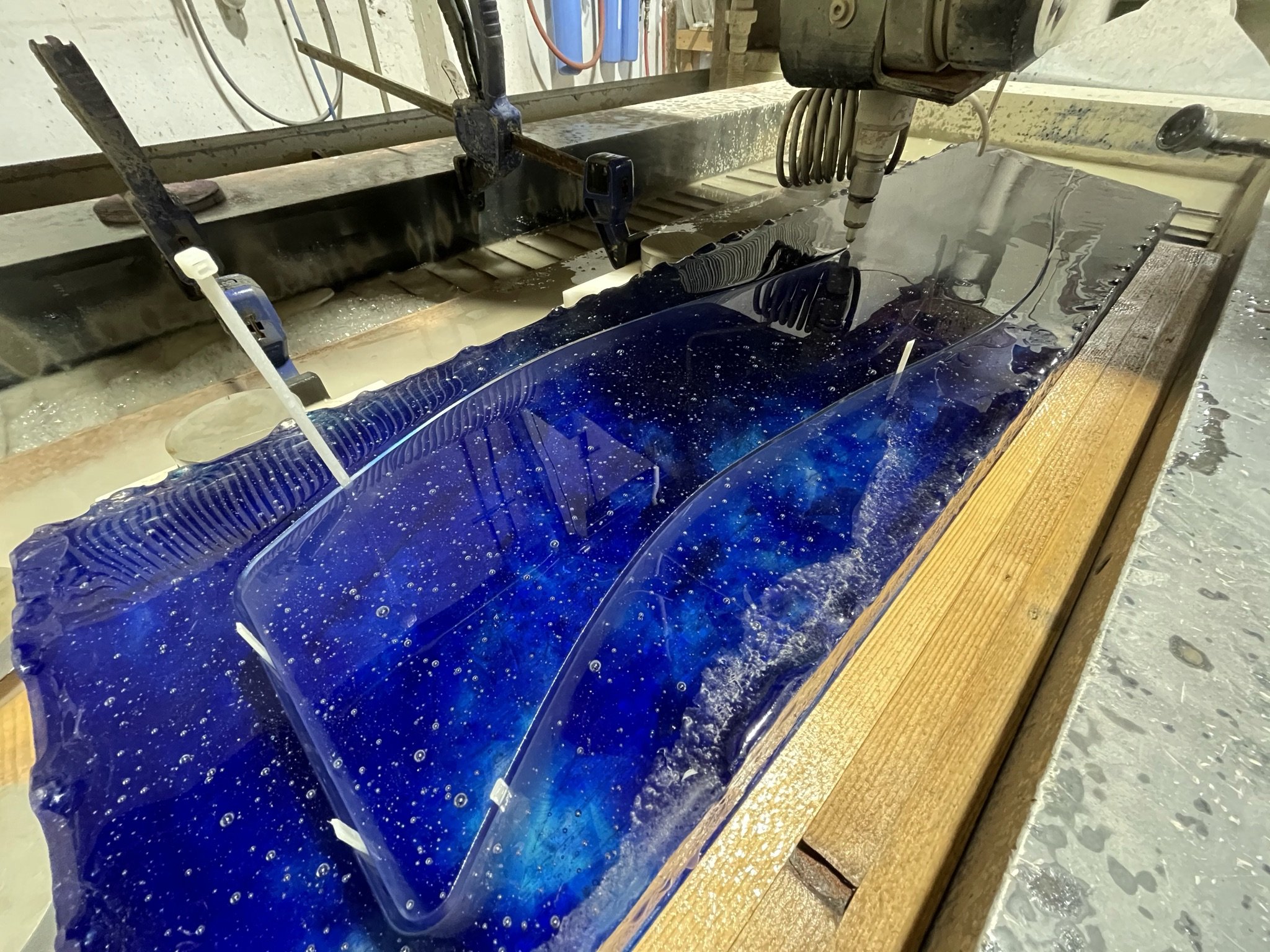

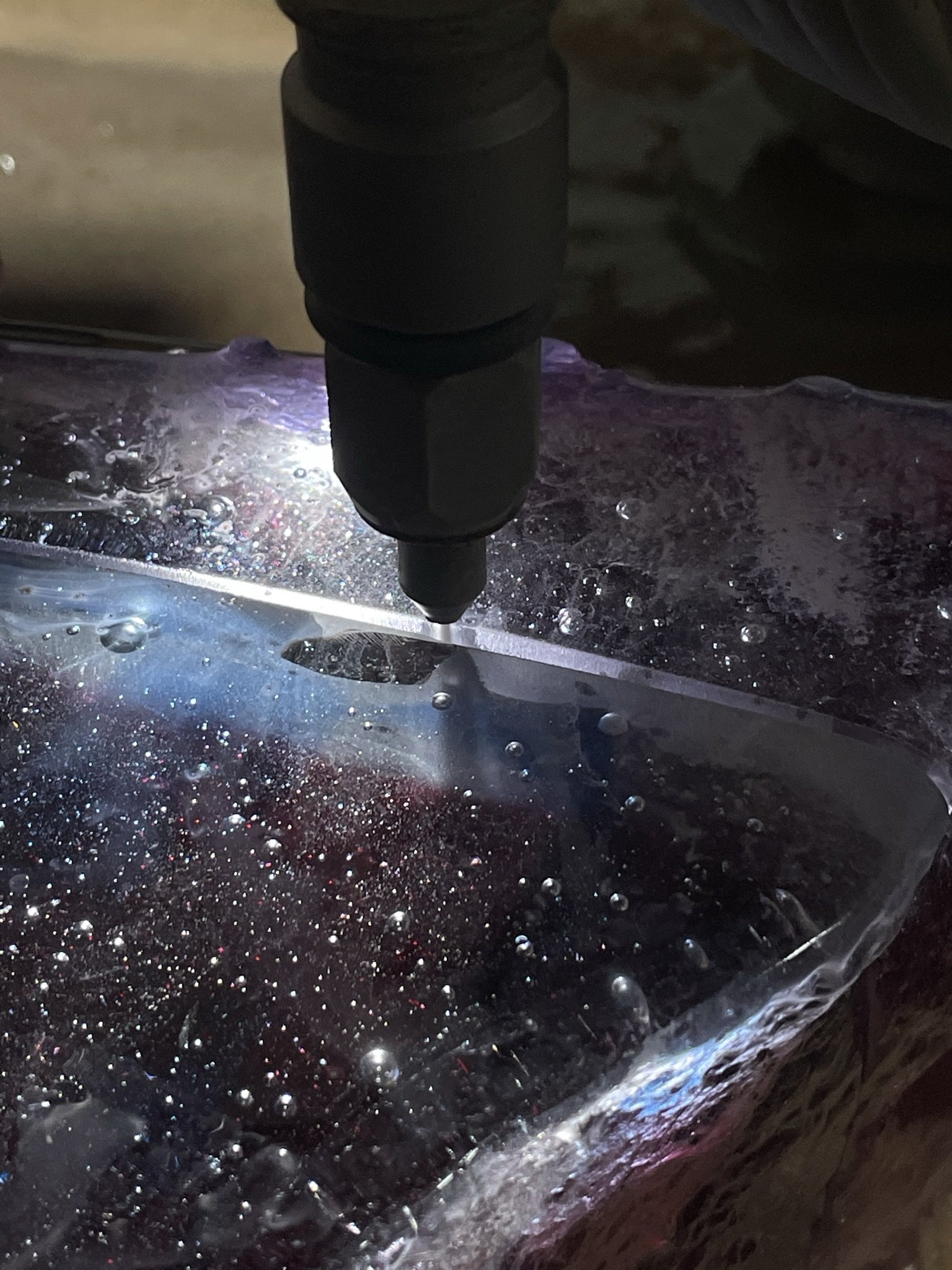

A waterjet utilizes a high pressure stream of water to erode a narrow line in 2D material. To cut a wider range of materials from tool steel to titanium to foam, a granular (garnet) abrasive is added to the waterjet, increasing the cutting power. Because the abrasive is added at the nozzle, it is simple to switch between water only and abrasive waterjet cutting. This flexibility greatly enhances the versatility of a waterjet machine, as it can easily switch from cutting ½" foam to 4" titanium. The use of integrated CAD/CAM technology ensure parts are made to spec.

MATERIALS

The list below is a brief overview of the different types of materials that frequently come through the shop. If you have a project that requires a material that didn’t make the list feel free to reach out and we’ll see what we can do.

We are happy to answer any questions.

BRITTLE:

Plate Glass

Art Glass

Ceramic Tile

Limestone

Granite

Marble

Plexiglass/Acrylic

SOFT:

Foam

Rubber

Neoprene

Nylon

HDPE

UHMW

Polycarbonate

Polyurethane

PVC

Vinyl

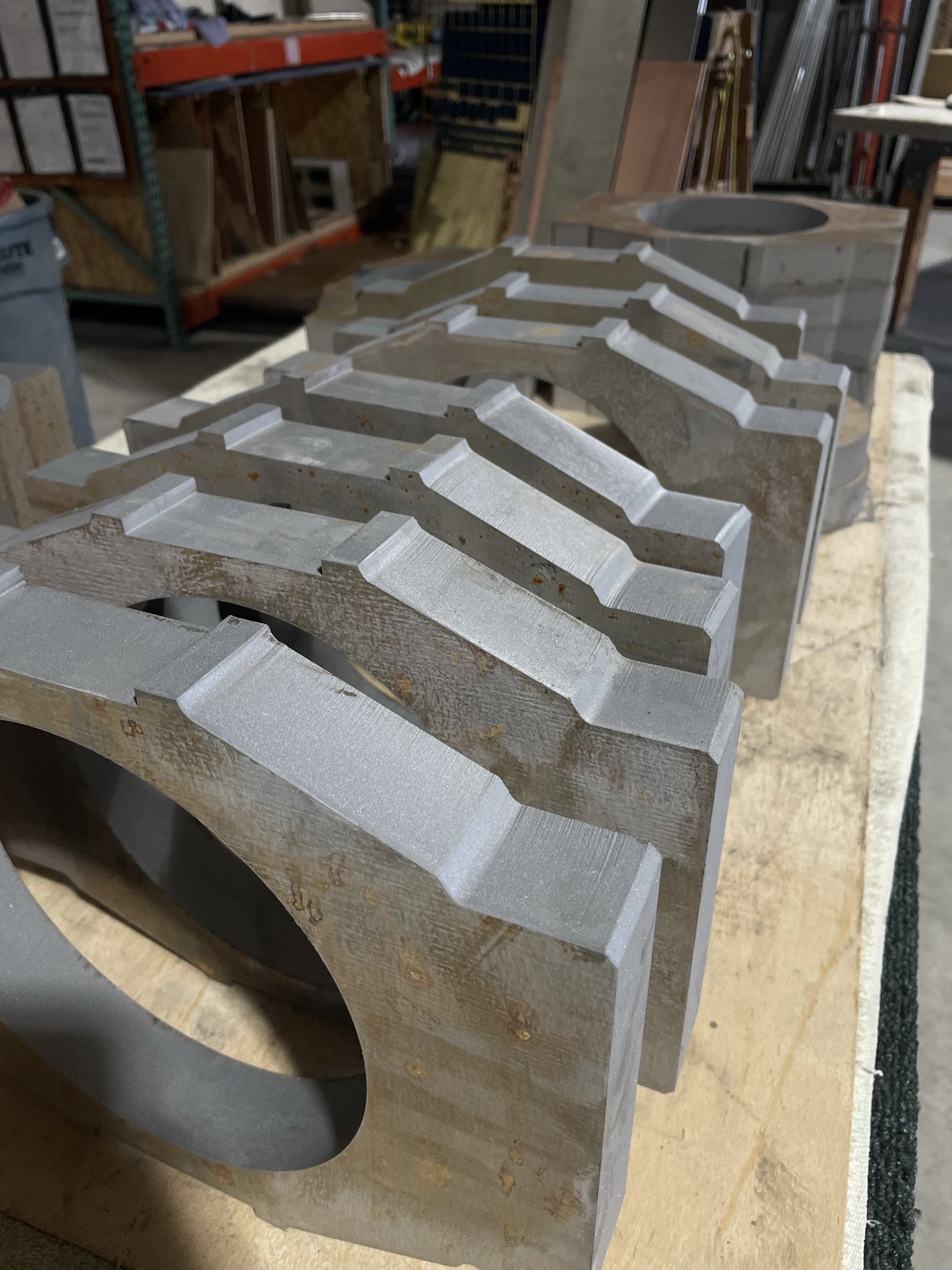

METAL:

Aluminum

Brass

Bronze

Copper

Stainless Steel

Mild Steel

Tool Steel

Hardened Steel

Tin

Titanium

PROJECTS

Heat Treated 17-4

Bullseye Glass - Serpentine Project